Roanoke Residents - Learn Lean Six Sigma’s History Here

Contact Us

It can be hard to read about Lean Six Sigma History since it takes a lot of research to find the right articles and make sure the information is reliable. In fact, due to misinformation and how people organize what is learned, many believe that everything was created in Japan using the Kaizen methodology. This is a false assumption, of course. Instead, the Kaizen methodology is what gave rise to the LSS methodology. We have been using LSS since the 1980s at Lean Six Sigma Curriculum for Roanoke High School Students of Virginia, so rest assured we know where it came from and how Kaizen plays a part in all of this, but not how most people think.

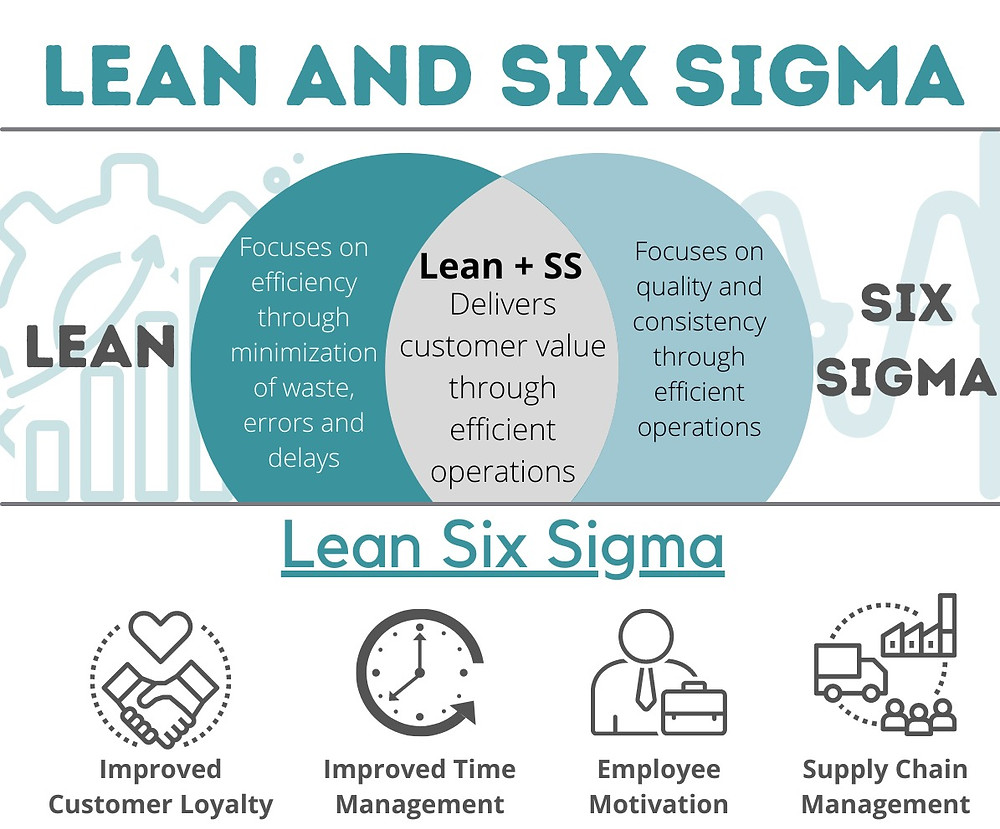

First, you must understand that this methodology was created to help companies prioritize customers and increase earnings. It combined the principles and structures from two major methodologies: Six Sigma and Lean.

If done right, the methodology can help reduce costs and eliminate waste. Throughout the entire process, it is important to maintain quality and performance.

Lean Six Sigma combines the best of Six Sigma and Lean while adding additional principles to address the weaknesses of each method.

Many people believe LSS is Japanese due to the Kaizen method and other Japanese philosophies. They helped improve Japan’s manufacturing industries by encouraging companies to think about customers’ needs and helped reduce costs. This led to increased production and manufacturing. Japanese industries were at the top in the 1980s, when American industries were struggling, leading to the creation of LSS to compete with Japanese industries.

When Was LSS Created, Then?

Understanding where LSS is derived from Six Sigma and Lean, which are well-known concepts that have existed for decades, is key. Toyota developed Lean in the 40s as a way to reduce non-value-adding activity.

Lean believes employees should be actively involved in organizational change to foster excellence, reduce waste and eliminate processes that aren’t worthy.

Lean believes continuous learning and improvement is one of the most important pillars for ensuring everyone is happy, achieves the desired results, and maximizes resources.

Toyota Production Systems (TPS) was the first to create this Lean methodology. Japanese Taiichi Ohno also founded it. Henry Ford’s innovations, Business Process Redesign, and other business process designs were the key ingredients to Lean and respective companies utilizing it.

This is how Lean works:

- Lean starts with understanding your customer’s added value and how you can satisfy it.

- The process flow and the value stream are both mapped.

- This step will allow you to identify waste and reduce it.

- Next, you will need to set up the system so that customers can request items and ensure everything is efficient.

- Employees will be able to identify areas they need to improve and then work together to fix them.

Lean is based upon all of the above. Six Sigma, however, is more data-driven. Motorola invented the method, and General Electric successfully used it in the early 1980s.

Six Sigma’s structure revolves around the DMAIC option, which stands for Define, Measure, Analyze, Improve, Control. This is useful for manufacturing but also in other industries to automate and reduce waste while improving cycle and process efficiency.

6 Sigma was also created a few years before LSS.

LSS was born out of this understanding. It was a solution to how Japanese companies innovated, improved, and got better products while still satisfying customers.

LSS brought together Lean and 6 Sigma elements and added additional ones to improve their results.

LSS Takes Over The USA

LSS was created to enable American companies to compete against Japanese manufacturers. As we have already mentioned, it is a mixture of two existing methods, and it was developed in the United States before any other country incorporated it.

This added insight and efficiency to the manufacturing industry and this combination enabled growth without compromising customer satisfaction.

When it was first developed, Lean Six Sigma was primarily used in manufacturing, but today, practitioners even get better results on their own projects when they follow Six Sigma’s structure.

Schools and educational institutions can design systems that are more efficient, simpler, and easier to use. LSS can also be taught to students to improve their job prospects, career options, and overall opportunities.

Participating in Lean Six Sigma can bring you many professional and personal benefits. If you are interested in learning more about this industry or getting involved, contact Lean Six Sigma Curriculum Pros of Roanoke.